Tuning the mechanical microenvironment to guide biological responses

Regenerative medicine research has focused on using stem cells and biomaterials to repair tissue injuries. The biomechanical environment, which affects individual cells to entire tissues and organs, controls the injury site, including biological activity, cell formation, differentiation, and proliferation.

Innovative approaches such as tissue engineering have emerged to address tissue defects and promote regeneration. It involves implanting cells into a specially designed scaffold, mimicking the target tissue’s chemical, physical, and mechanical properties at the scale of cellular interactions.

Our technology is instrumental in optimizing scaffolds, ensuring their mechanical properties align with tissue requirements, support effective cell-biomaterial interaction, and comply with the criteria for successful drug delivery for tissue regeneration.

Biomaterial stiffness must be tuned to match the mechanical properties of natural tissues, ensuring optimal cell function, integration, and stability for applications in regenerative medicine.

Monitoring viscoelasticity allows biomaterials to mimic the behavior of natural tissues, promoting their functionality, compatibility, and stability.

Topographical cues have a major impact on biological responses.

Stress relaxation characterizes how materials reduce stress under constant strain over time. Measuring stress relaxation provides insights into the time-dependent mechanical properties of materials and how they respond to mechanical loads.

Creep describes the gradual deformation of materials under constant load. Evaluating the creep behavior of materials helps understand the long-term mechanical changes associated with their performance and durability in various applications.

Incorporating mechanical measurements will:

Design and monitor the optimal microenvironment to promote tissue regeneration.

• Measure the mechanics of soft biomaterials at the cellular scale.

• Improve quality control at every stage of the biomaterial lifecycle.

Advance early-phase testing and validation of implants and drug delivery systems.

• No need for extensive sample preparation.

• Preserve sample integrity through non-destructive analysis at various workflow stages.

• Correlate mechanical data with subsequent downstream experiments.

We enable researchers to get the most out of their time and efforts by providing solutions that meet their diverse and versatile needs.

Powerful insights in a small package. Discover our compact, standalone Piuma platform.

Combine unique mechanical insights with the imaging equipment of your choice. Our Chiaro platform is the perfect collaborator.

Discover high-throughput mechanical screening that seamlessly integrates with existing biological workflows, effortless correlation, offering high resolution and reproducibility.

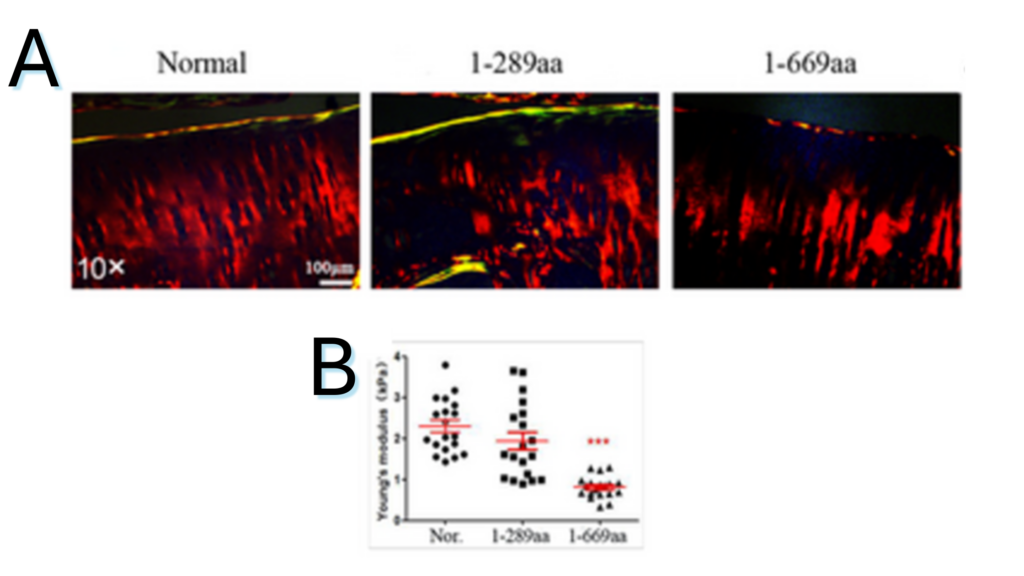

Figure 1.1. Articular cartilage injury after injections of HDAC4-NT fragments (1-289aa and 1-669aa treatment). (A) Representative Sirius Red staining results. (10×; scale bar: 100 μm). (B) Average Young’s modulus of groups was quantified (n = 6).

Note. Adapted from “The N-terminal fragment of histone deacetylase 4 (1-669aa) promotes chondrocyte apoptosis via the p53-dependent endoplasmic reticulum stress pathway”, Guo, L., 2024 J Cell Mol Med. Oct;28(20):e70135. doi: 10.1111/jcmm.70135. . © The Author(s) 2024. This is an open access article under the CC BY license.

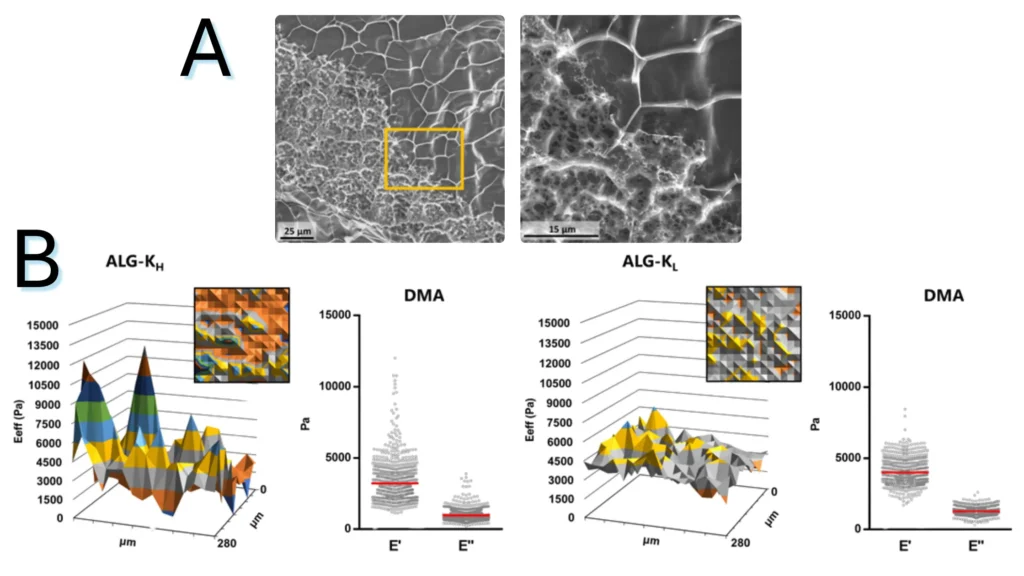

Figure 1.2. Characterization of alginate hydrogel’s structural and mechanical heterogeneity (A) CryoSEM of ALG-KH hydrogels, showing distinct denser/loser regions. (B) Surface mechanical properties of ALG-KH and ALG-KL hydrogels obtained by static (effective Young’s modulus, Eeff) and DMA (elastic, E′, and viscous, E″, components) nanoindentation measurements.

Note. Adapted from “Microstructured click hydrogels for cell contact guidance in 3D”, Neves, MI, 2023, Mater Today Bio. 2023; 19:100604. doi:10.1016/j.mtbio.2023.100604. © 2023 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY license.

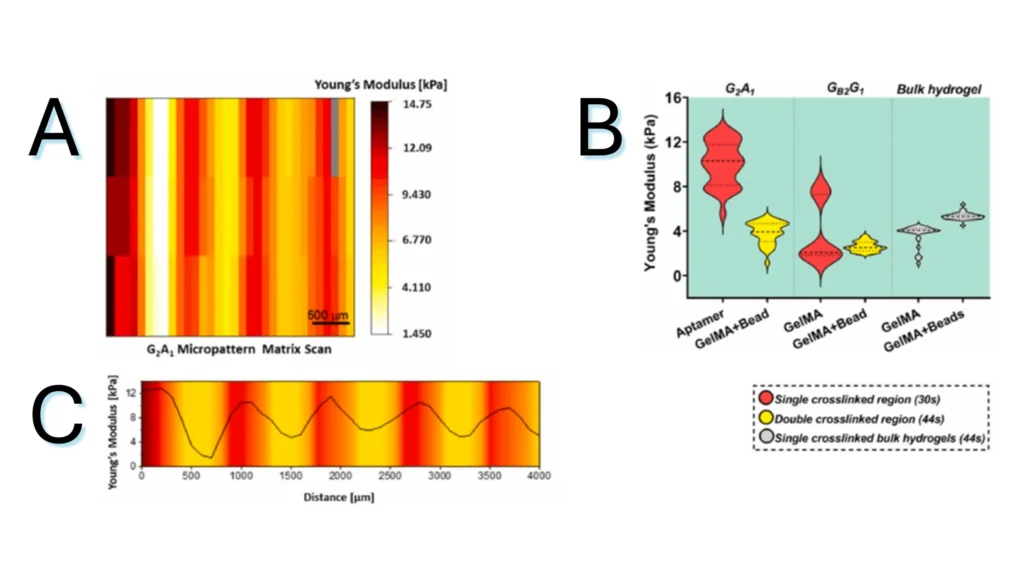

Figure 1.3. Micromechanical behavior of bicomponent micropatterns in hydrogel scaffold. (A) Matrix scan of Young’s modulus of the crosslinked micropattern, revealing the mechanical difference between the aptamer and GelMA regions. (B) Young’s modulus quantification of different regions in photocrosslinked aptamer/GelMA micropatterns or bulk GelMA/GelMA mixed with fluorescent microbeads, revealing the effect of aptamer content on the extent of crosslinking. (C) Young’s modulus profile across the long axis of a micropattern depicting the gradual variation in Young’s modulus magnitude between regions.

Note. Adapted from “Spatial control of self-organizing vascular networks with programmable aptamer-tethered growth factor photopatterning”, Rana, D, 2023, Mater Today Bio, 19:100551. doi: 10.1016/j.mtbio.2023.100551.24. . © 2023 The Authors. This is an open access article under the CC BY license.

Whether your focus lies on mechanical measurements and characterization at the cell scale, or you work with muscle tissues, our platforms offer you precise, fast, and accurate outcomes. Discover more about how our products can help you accelerate and achieve your research goals.

With a wide range of application areas, across an array of samples, for various disease areas and testing needs, we can provide you with precise insights into mechanical cues to advance your translational research. Learn more about our applications here.

We are a growing team of 60+ passionate people, headquartered in Amsterdam, the Netherlands. Learn more about our journey so far, meet our team of professionals, and our career opportunities.

Resources

Contact